Introducing the SiA M series Solar

Powered Chemical Injection Pump &

associated monitoring and control equipment

Power from The Sun

The Solar Injection PUMP ( SiP ) M series has been developed to answer the demand from producers

for an environmentally friendly alternative to Gas Driven Chemical Injection Pumps that can utilise

re-newable energy. However, the benefits do not end there:

Environmental Benefits:

l Eliminates the requirement to collect and dispose of harmful discharges from Gas Conditioning Equipment

l Eliminates the venting of Drive Gas to atmosphere and the associated environmental issues

l Eliminates the requirement for Drive Gas Conditioning Equipment

Initial Design Benefits:

l Solar Array provides power for associated Instrumentation

l Solar Array provides power for Remote Monitoring & Control Systems (SCADA)

Operational Cost Benefits:

l Eliminates expensive Drive Gas Wastage

l Greatly increased reliability and extended service intervals

l Greatly increased accuracy of metering with much more control (Electronic Control)

l Easily monitored and controlled remotely with iSAT

SiA Solar Drive Benefits:

l Reciprocating Force provided b y 3 16 SS Cam-shaft with n o over-hung loads

l Cam-shaft supported either end b y oversiz e d sealed s i ngle row d e ep grooved bearings

l Cam-follower oversized and guided b y self l ubricating bearing Contact bet w e e n

l Cam-foll o w er & Cam-shaft b y oversiz e d single row d eep groove bearing

l Drive Ass e mb l y ful l y s ealed against dust, w e ather and off-shore environments

l Drive Ass e mblies are modular and can accommodate up to 4 Pumps per drive

l Drive Ass e mblies can accommodate 2 Gearmotors each

l Drive Ass e mblies can be interconnected allo w i n g for up to 16 pumps

l 12 or 24 volt DC stand a rd off the shelf gearmotors

l AC & Hazardous Area Units available

l Can be retro-fitted to existing Morgan Chemical Injection Pumps

l 0-10 0 % M e chanical Stroke/Volume Adjustment

SiA Controller Benefits

l Available with or w ith o ut Modular Timer w ith 1-60 c y cles per minute adjustability

l Can be fully integrat e d with end user control & monitoring s y stems

l Ful l y integrates w ith SiA’s iSAT Satellite Monitoring & Control S y stem

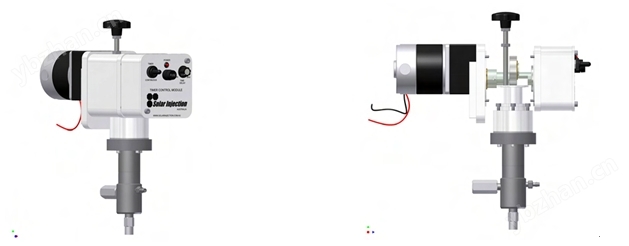

Some more detail:

The standa r d motive force of the Drive Assemb l y consists of a PMDC motor driving through an i n tegrally mounted planetary gearbox. This Gear-motor mounts dir e c t ly to the drive case’s fla n ge mount and the

drive shaft connects to t he Drive C a m-shaft via a keyed connection. The Cam-shaft is supported either

end by oversized s e aled bearings so as to elimi n ate all overhung loads. T his greatly increases t h e life of the Gear-motor’s gear b ox which can be an iss u e with other drives.

The Cam-s h aft has ano t her sealed ov er sized b e aring acting upon a Cam-follower. The Cam- follower

has a large bearing sur f ace area a n d is suppor t ed by a sliding, self-lubricating bush of Ertalyte . T he Cam

-follower is directly co n nected to t h e Chemical Injection P u mp’s plunger and is driven in the pr e ssure

stroke by the off-set in t he Cam-sh a ft. The con n ection bet w een the Cam-follower and the Cam-shaft is a rolling one b y w a y of the large roller bearing. T h e Cam-follower is returned for the s u ction str o ke by an internal spring once the Cam-shaft has rotated p ast the maximum press u re stroke point.

Because the Drive Case is manufac t ured from square holl o w tube, we are able to mount a C h emical Injection P u mp on any a nd all of the 4 faces. Th i s means one Gear-mo t or can drive up to 4 pumps per drive case. Because all drive case components are over-designed, it is practical t o inter-connect up to 4 drive cases to be driven from the one gear-motor provided the gear-motor has sufficient torque a nd

power capabiliti e s. It i s also possib l e to mount a second dri v e gear-motor horizontal l y opposed to the other, so as to increase t he amount of power available. This in turn, allo w s us to use various voltages and AC current motors both as stan d ard, Hazardous Area or client s p eci a ls.

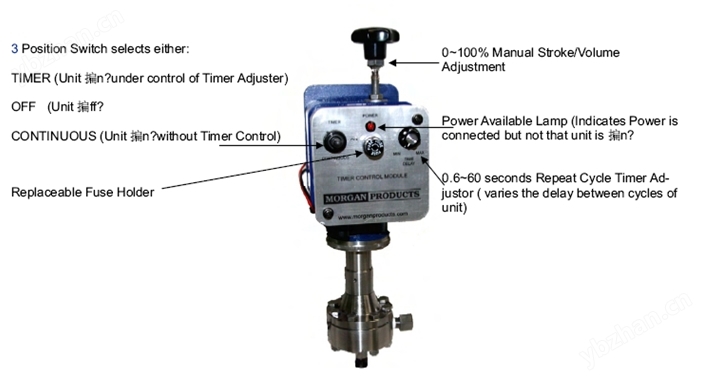

The standa r d Timer M o dule can be mounted directly on the Drive Case or remotely. It is housed in the same square hollow tu b e material as the drive case. The 12 or 24 VDC module consists o f:

l A fuse hold e r

l An electronic encaps u l a ted timer

l An Off/Tim e r/Continuous selec t or switch

l A variable delay controller

l A Power available in d icator lamp

l Plug connections for p o wer supply and supply to gear-motor

The Solar Drive can be supplied wi t h or without the standard Timer Mo d ule. If the s t andard Timer

Module is n ot supplied, the Drive can easily be integrated in to a third p a rty’s control system providing

the correct supply voltage and amps are supplied to the Drive’s gear-motor. Alternatively, we can supply

an iSAT System that also fully inte g rates with o ur Drive. T h e following p ages desc r ibe how iSAT can be the solution be it a simple single u n it control to t h e very sophisticated m o nitoring & c o ntrol of numerous Chemical Injection Pumps remotely with Satelli t e/Int e rnet override from any PC connected to t h e world- wide web.

SiA is a systems integrator, so altho u gh we offer a component only supply facility, we mainly carry out complete design, buil d , installation a nd commission solutio n s. In other words and End-To-End S o lution

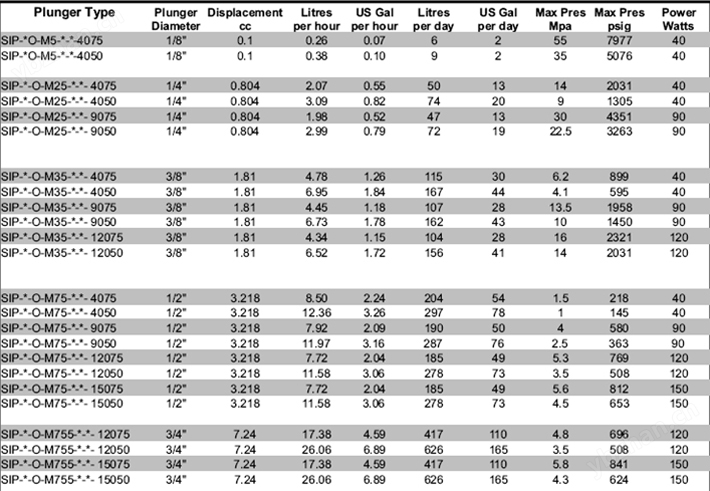

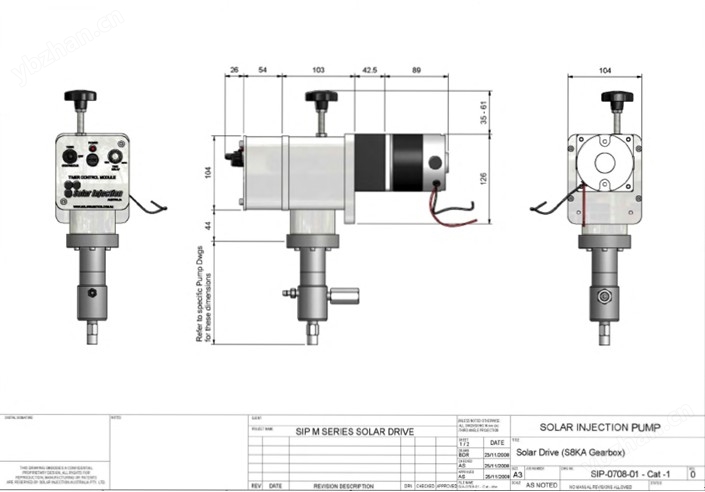

Dimensions of 40 watt models with either gearbox ratio

Note: Dimensions and data subject to change without notice. If critical, consult factory.

Dimensions of 90; 120; 150 watt models shown with either ratio gearbox

Note: Dimensions and data subject to change without notice. If critical, consult factory

Monitoring & Control ( iSAT)

SIA designs, manufactures and markets its own and OEM satellite communication modems & systems

for asset tracking, monitoring, and control applications. Our systems enable data messages to be sent

and received from small, low-powered terminals (often solar powered) over satellite and mobile phone

networks. Users receive near real-time notification of asset location, on-board information and alarms via

or via web user interface. The user determines the exact data to be collected and the frequency at

which it is transmitted and received. The same system allows messages to be sent to the remote located

modem and asset. This gives the system a 2-Way Monitoring & Control ability.

The iSAT System in more detail

The iSAT System can best be described as a near-real-time, 2-way, end-to-end wireless communication

system that facilitates complete M2M (Machine to Machine) interfacing and HMI (Human Machine Interfacing)

with all the attributes of a full SCADA system.

Typical Out-going messages from the RTU (Client Application) to iSAT :

Status of the various sensors, monitors and devices connected to the RTU 抯 I/O at

any specifically nominated time or event

GPS Position

Date & Time of the message

Date & Time of when the status (record) was taken.

Alarms generated by certain preset but variable conditions sensed by the RTU

Acknowledgements of messages received

Typical In-coming messages from the iSAT to the RTU:

Requests for instant messaging (Polling)

Changes to the Reporting intervals

Changes to Alarm Set Points

Switching Digital Outputs On or Off

Provisioning of new sensors

Over-The Air Programming

The iSAT SYSTEM and ORBCOMM gives remote asset monitoring & control a very low latency &

lower data transmission cost solution that can be accessed from anywhere there is an internet connection

l 137-150 MHz VHF Frequencies result in very reliable connections even in poor weather

l Very Low Latency (Near-Real-Time)

l 30 plus, Low Orbit Satellite Constellation gives excellent redundancy

l Low Power Requirements (Solar Powered Systems Available)

l Data Message size up to 8 Kbytes

l i SAT 2 way Systems allowing for both monitoring & Control

l Web-based iSAT software gives access from any internet connection, world-wide

l All Data encrypted and secure

l Lowest cost Data Plans for any Satellite System

l Local Support

l Hardware (modems) costs comparable to GPRS (Cellular) types

l iSAT Software locally supported and able to customised

l End-To-End System design, assembly & installation available

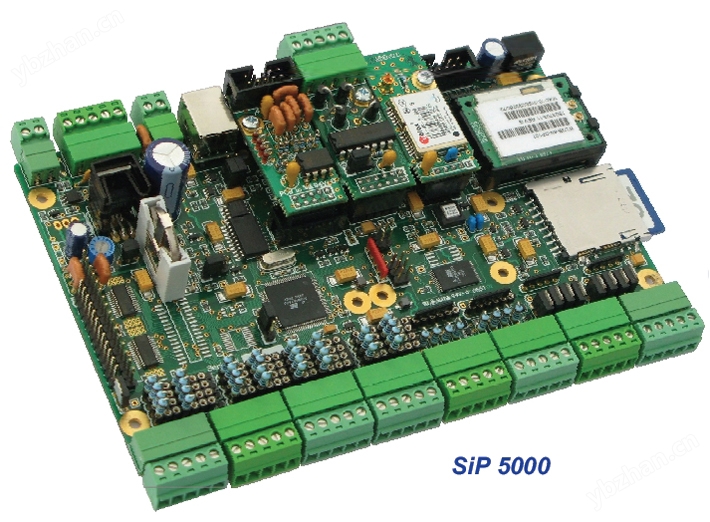

This is SiP 's most powerful Remote Terminal Unit available to date, The SiP 5000 is capable of making numerous

control decisions on site from multiple sensor inputs to numerous switched outputs. At the same time, the

SiP5000 can data-log and report back to a remote base utilising iSAT and the internet

l Based on the JED 256 PC Board which is designed and manufactured in PUMP and utilises the ATmega 2560 core CPU.

l ndustrial Strength Interfaces.

l 16 Analog ports which can also be digital inputs, 8 with pin change interrupts. (these can handle 2 phase Rotary Position Encoders).

l 16 other ports that can be either Digital In or Out. 4 have "In put capture"?

l Outputs can have up to 7 with Pulse Width Modulation

l Outputs are 10 amp FETs with built in High Energy Protection.

l Optional Text or Graphic LCD Display with Keyboard interface.

l Optional 2 Axis Accelerometer Chip for shock detection.

l Ultra stable Real Time Clock with temperature compensation.

l 4 RS232 Serial Ports with ESD & EMC protection.

l CPU RAM can be expanded to 64 Kbyte.

l 4/8 Mbyte DataFlash provide non-volatile data logging Memory.

l Optional SD/MMC interface can provide many Mbytes of removable data logging Memory.

l 12 volt Supply suitable for vehicles.

l Optional 24 volt environments can be accommodated.

l iSAT compatibility.